Photo-essays of several procedures:

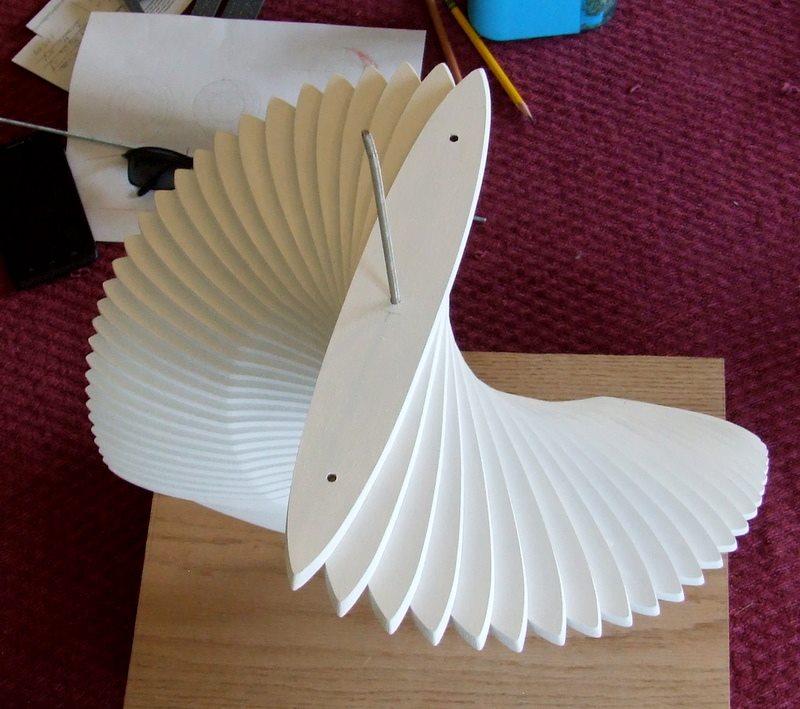

Into Flight

There were two goals in this piece: an expression of flight, and a metamorphosis of the Icon. It was first made fully into an Icon and then shaped to the new form. Future versions of this piece will be made in glass and steel. The following slides show steps in the process.

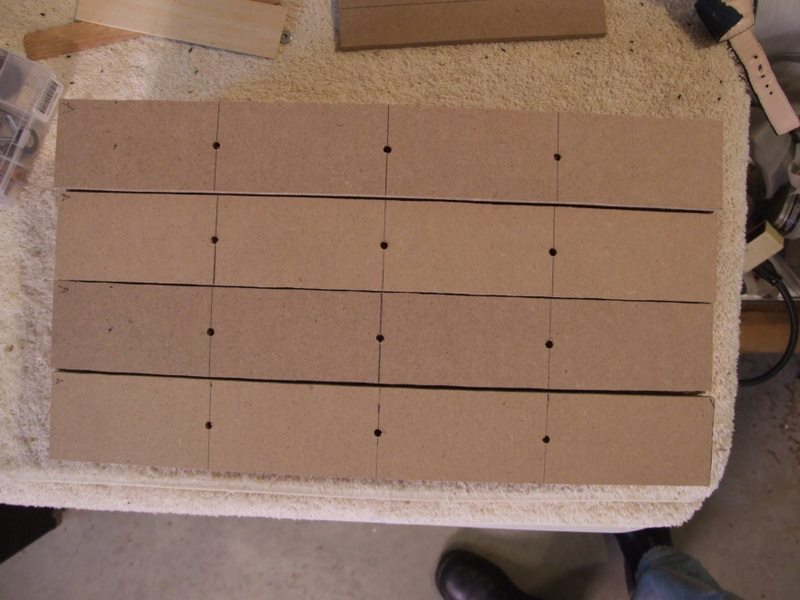

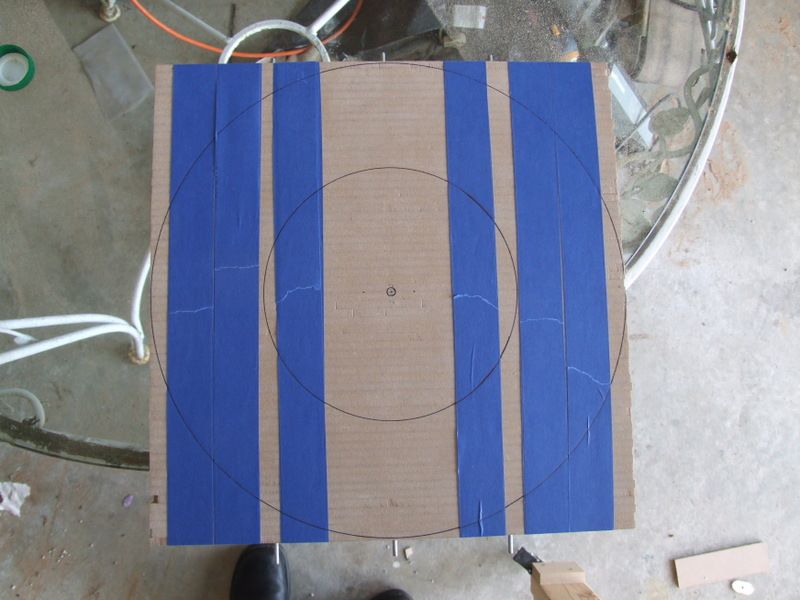

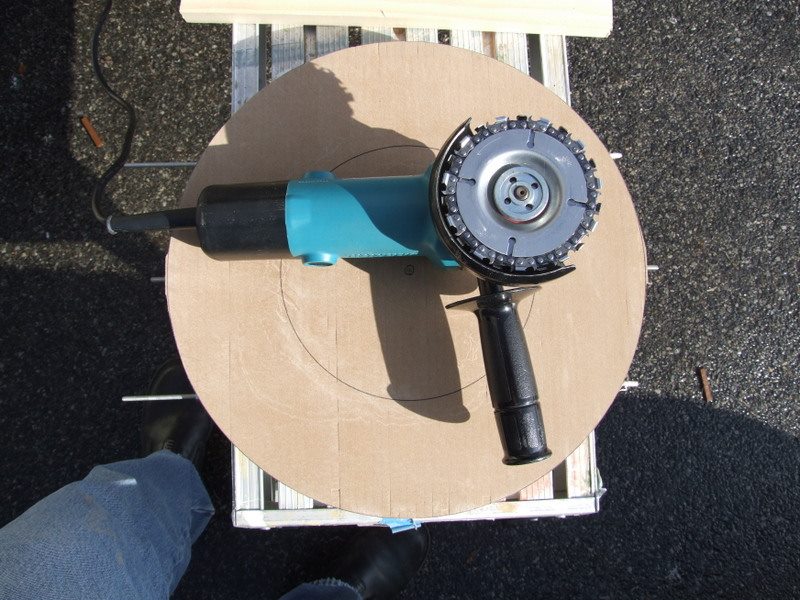

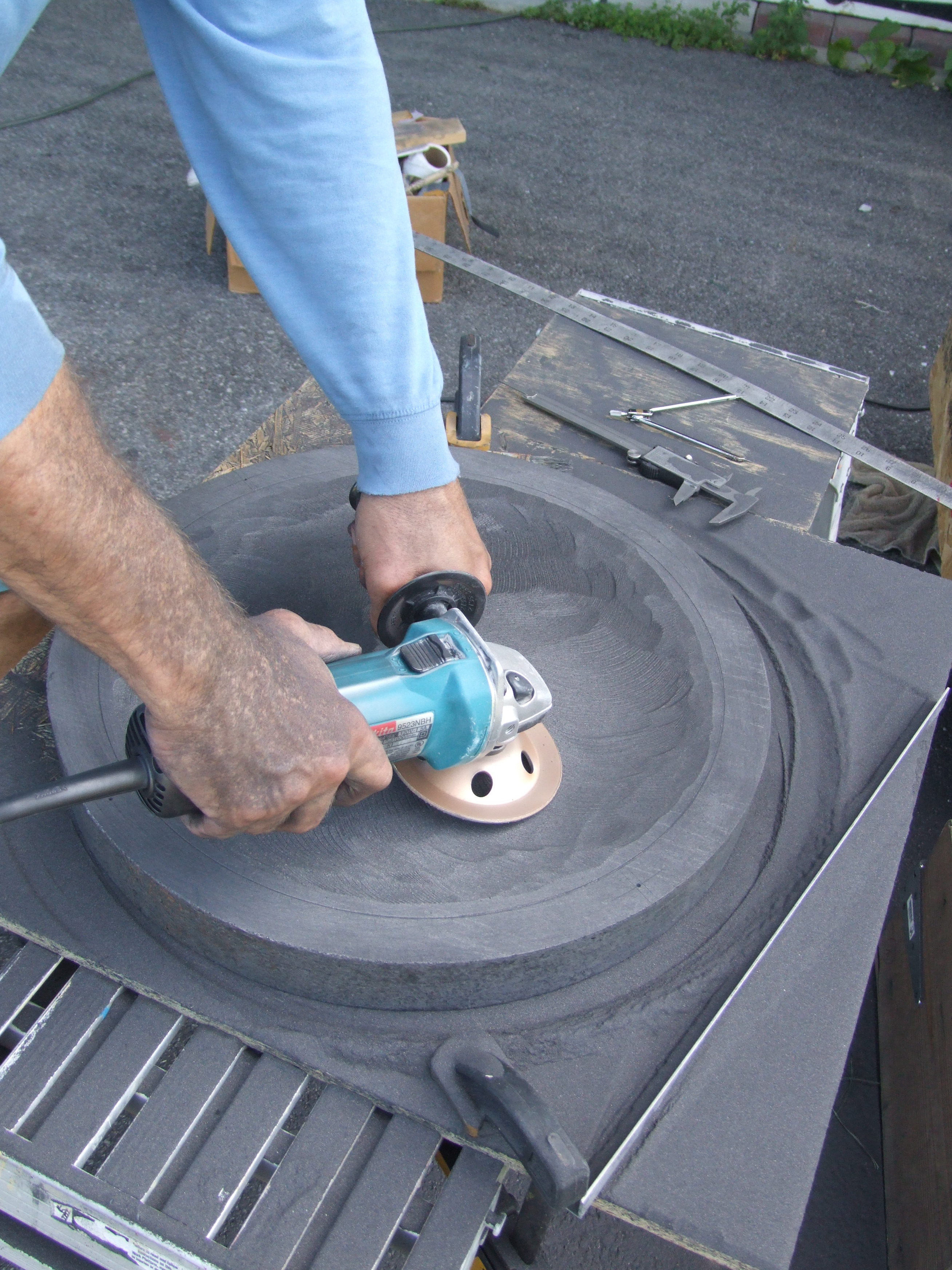

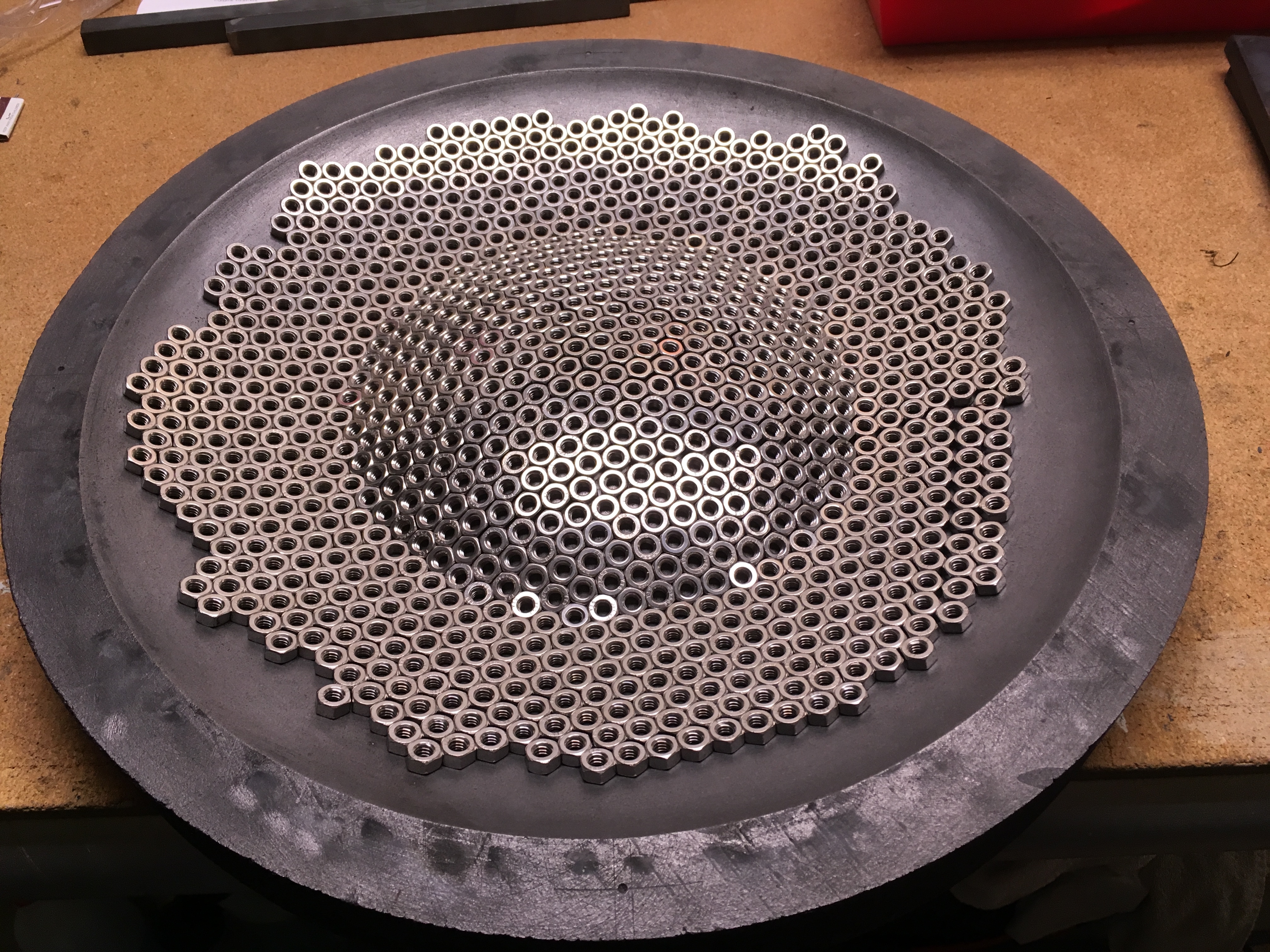

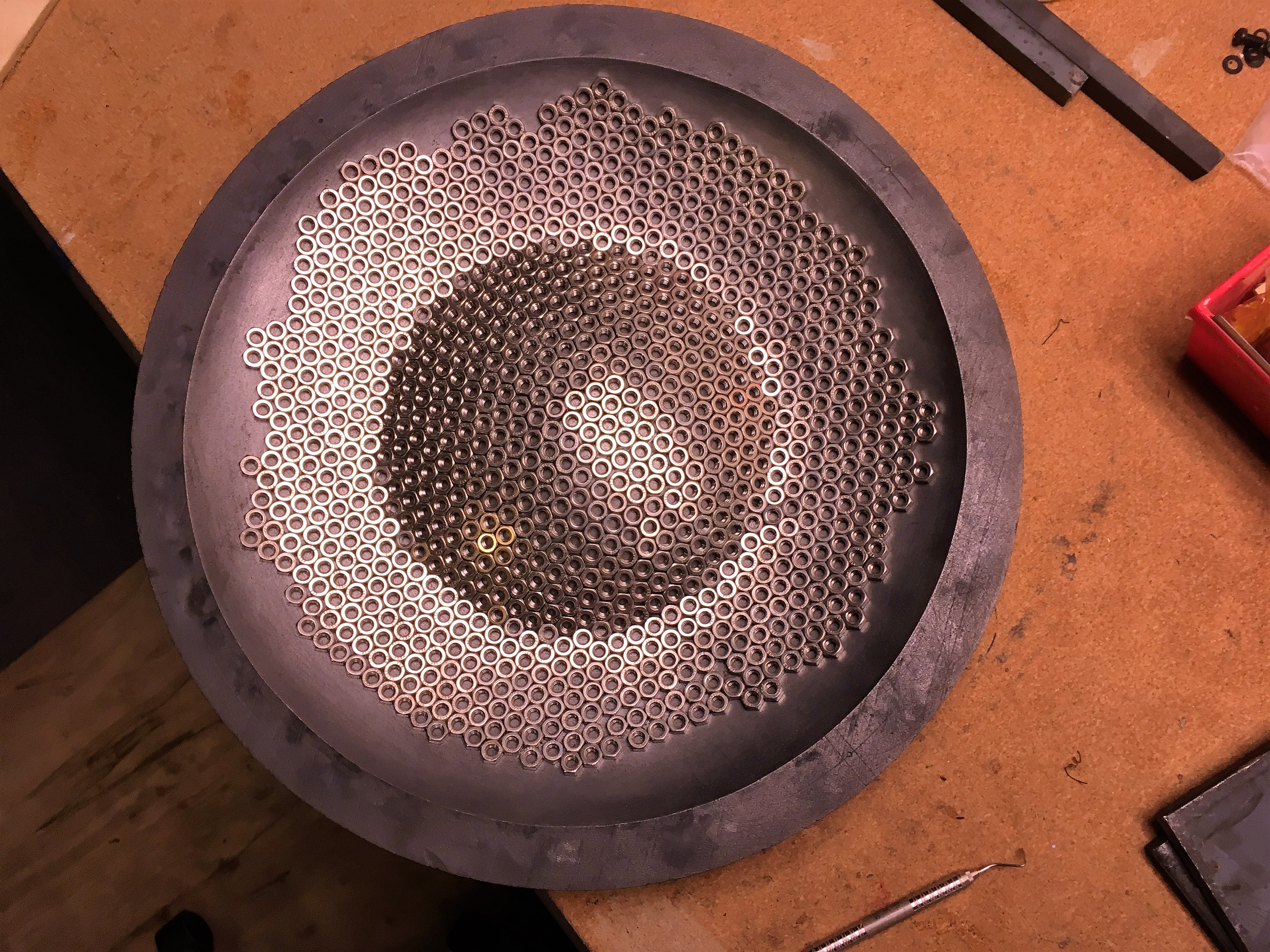

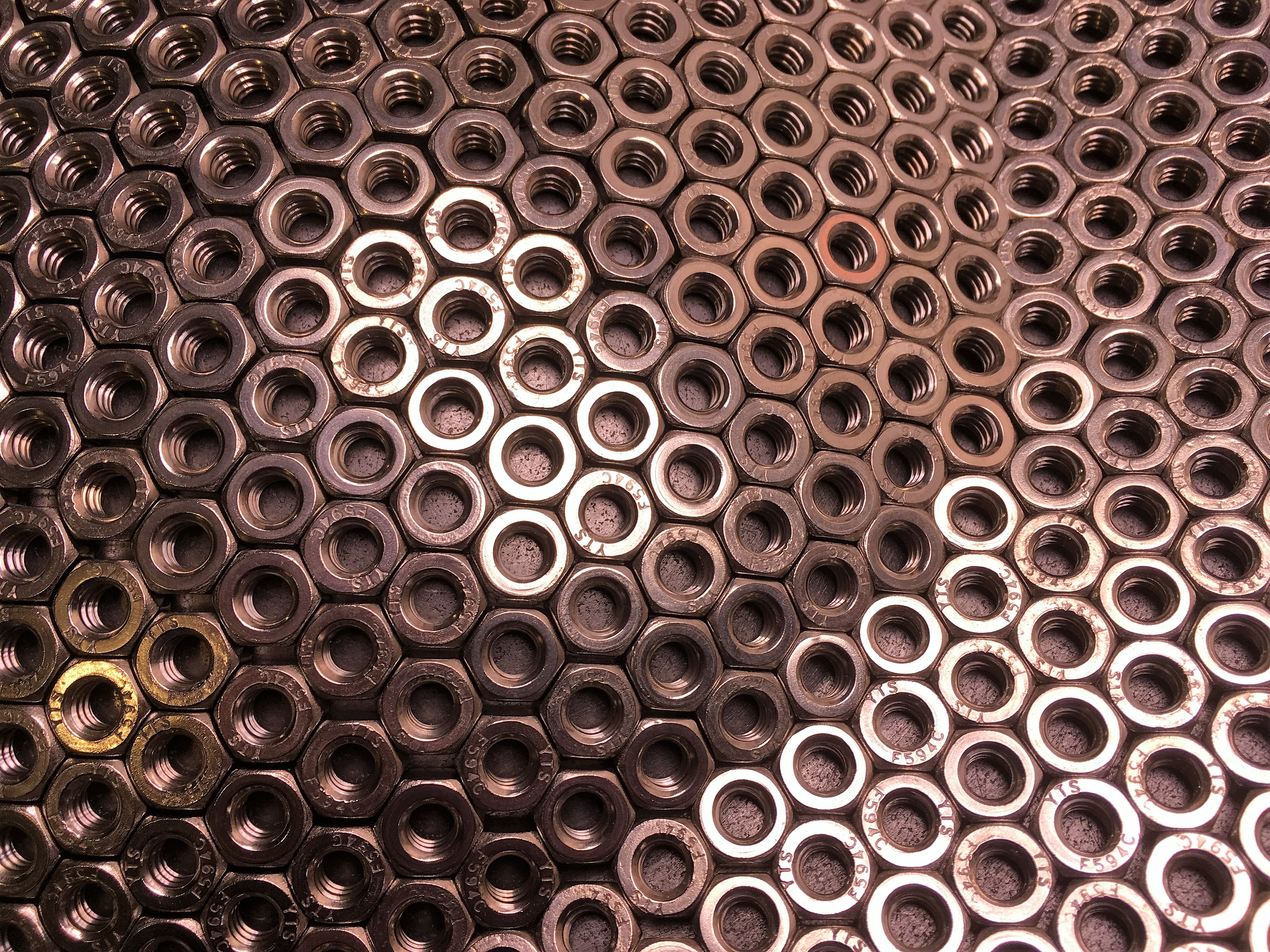

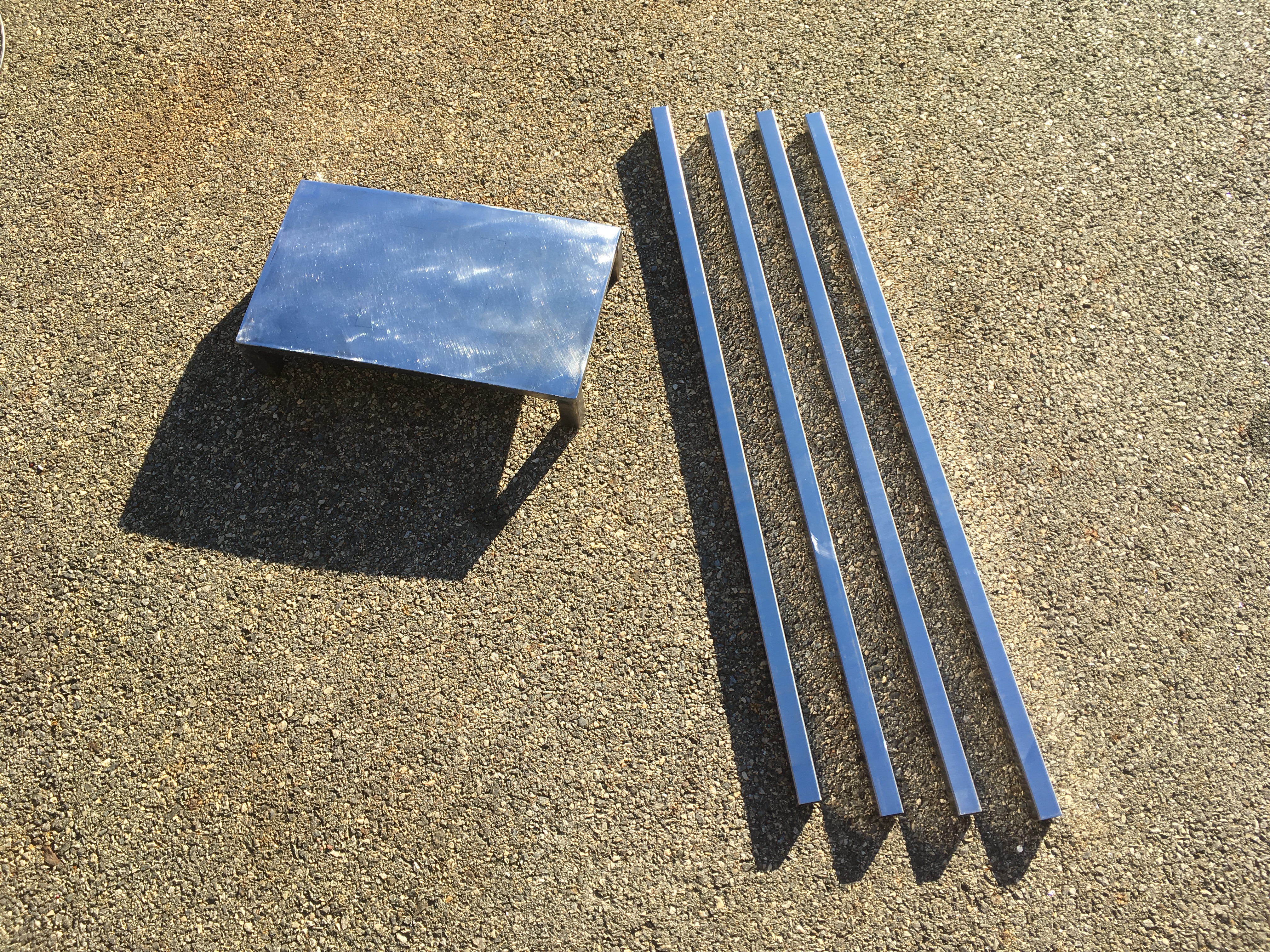

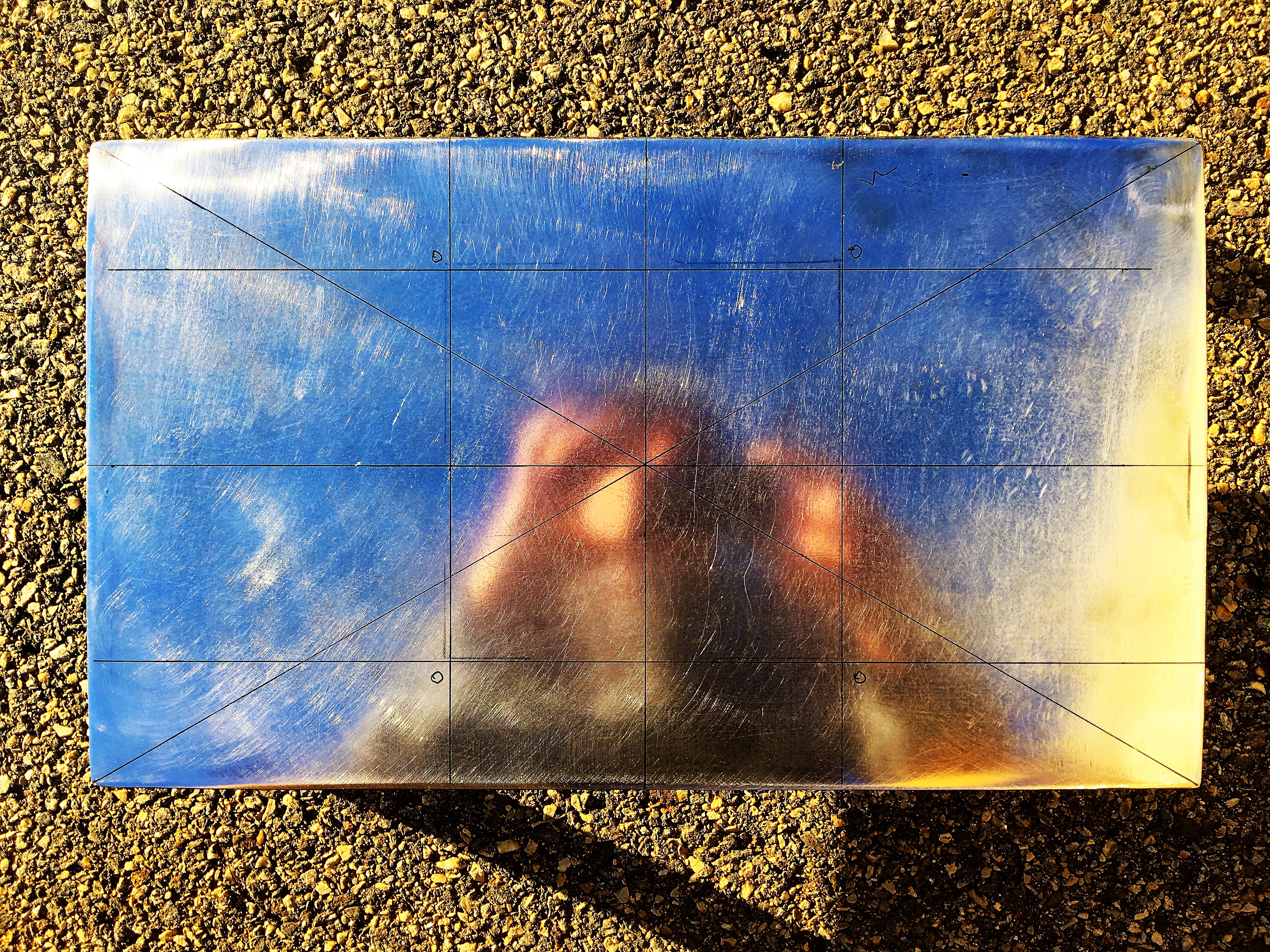

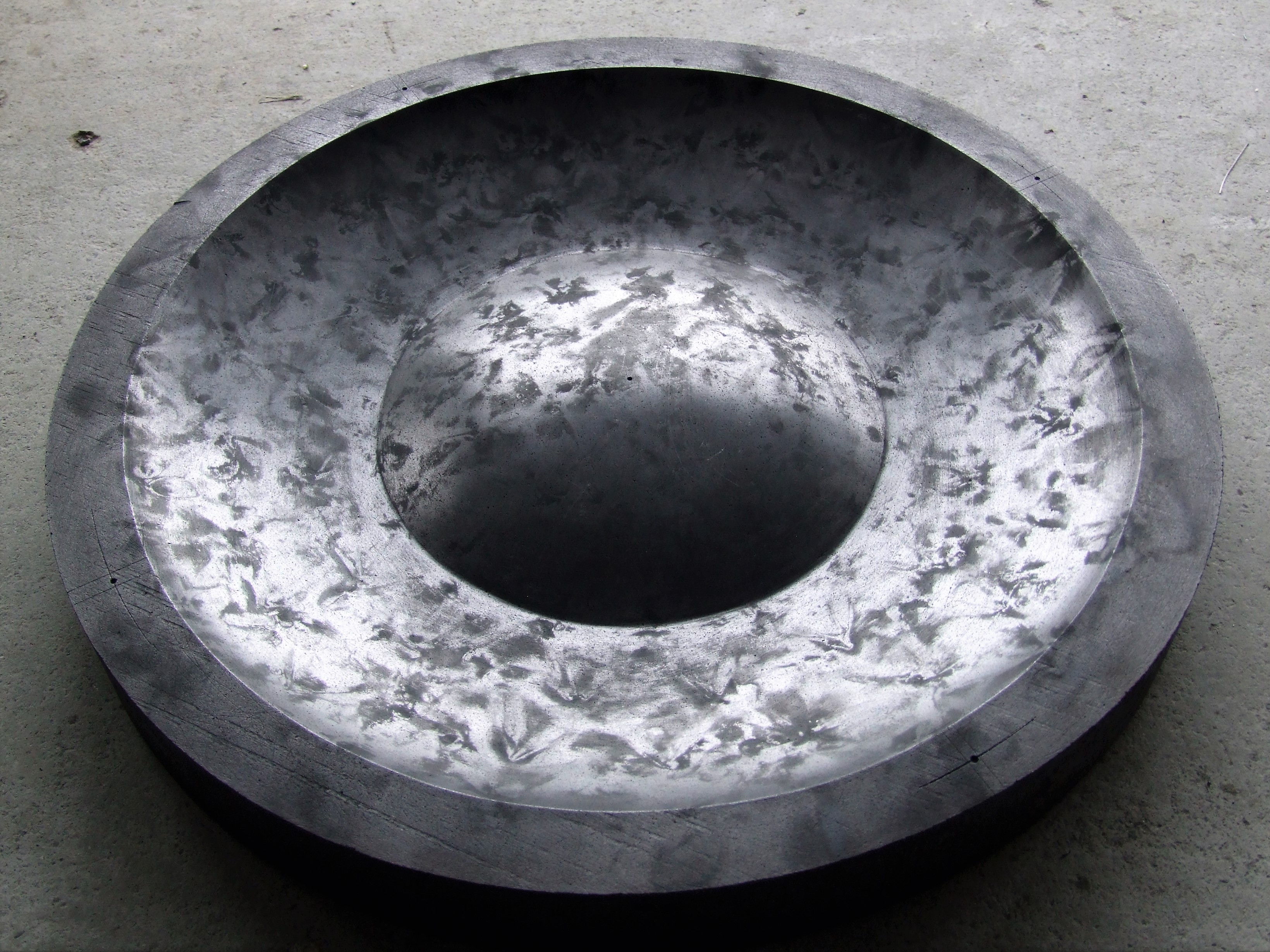

Graphite Molds

The current series uses a carved negative half-mold which can be worked repeatedly at high temperatures to create glass and metal sculptures. This is a relatively new process and three pieces have been produced so far. Simply carving the mold – which arrived as a 40 lb manhole cover sized plate - was a two month period of sessions and tasks. These ranged from carving an initial 'positive' plug in foam as a concept piece, to sketching and cutting plywood templates with which to determine that the 'negative' mold in graphite matched the concept piece.

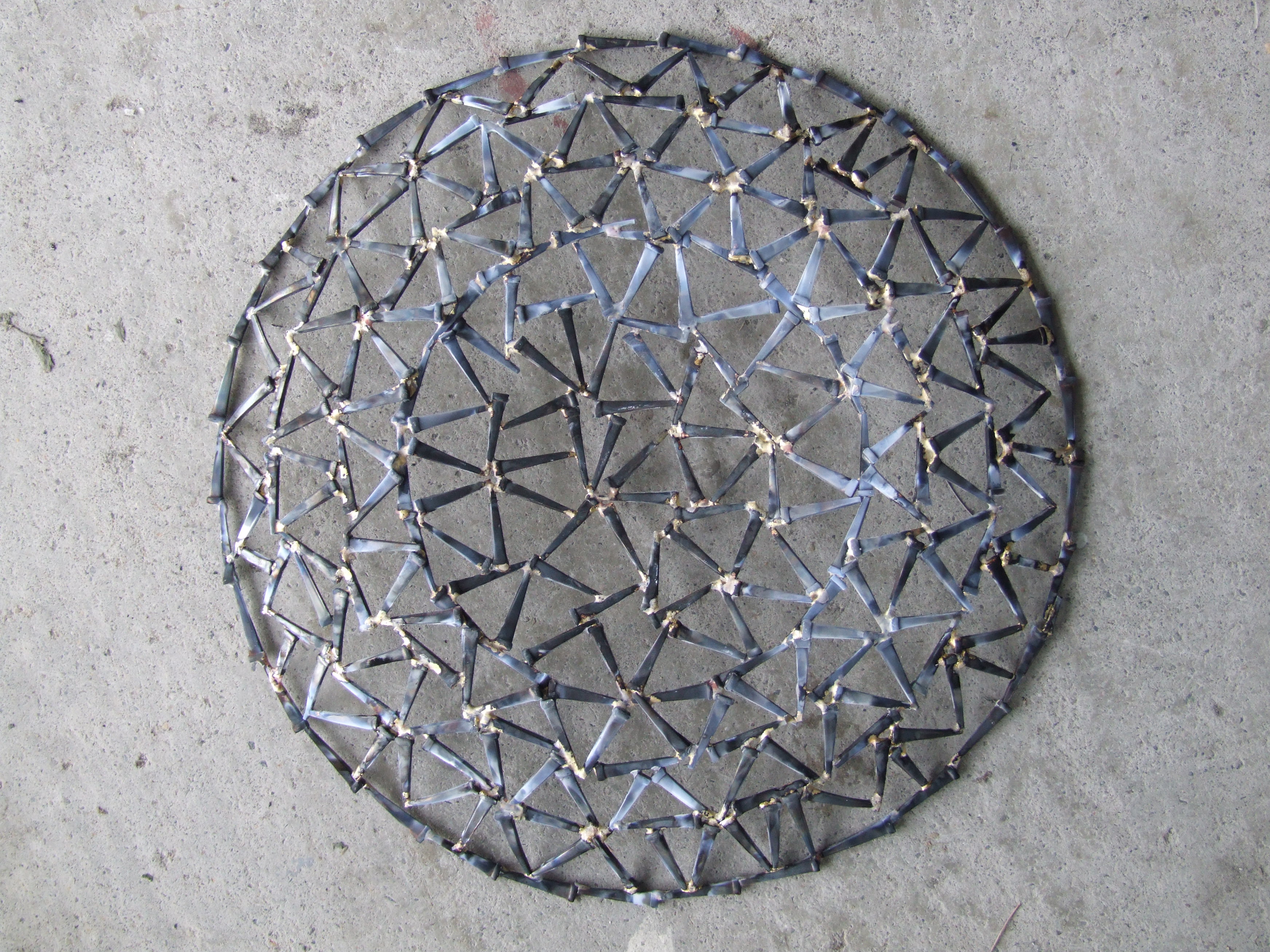

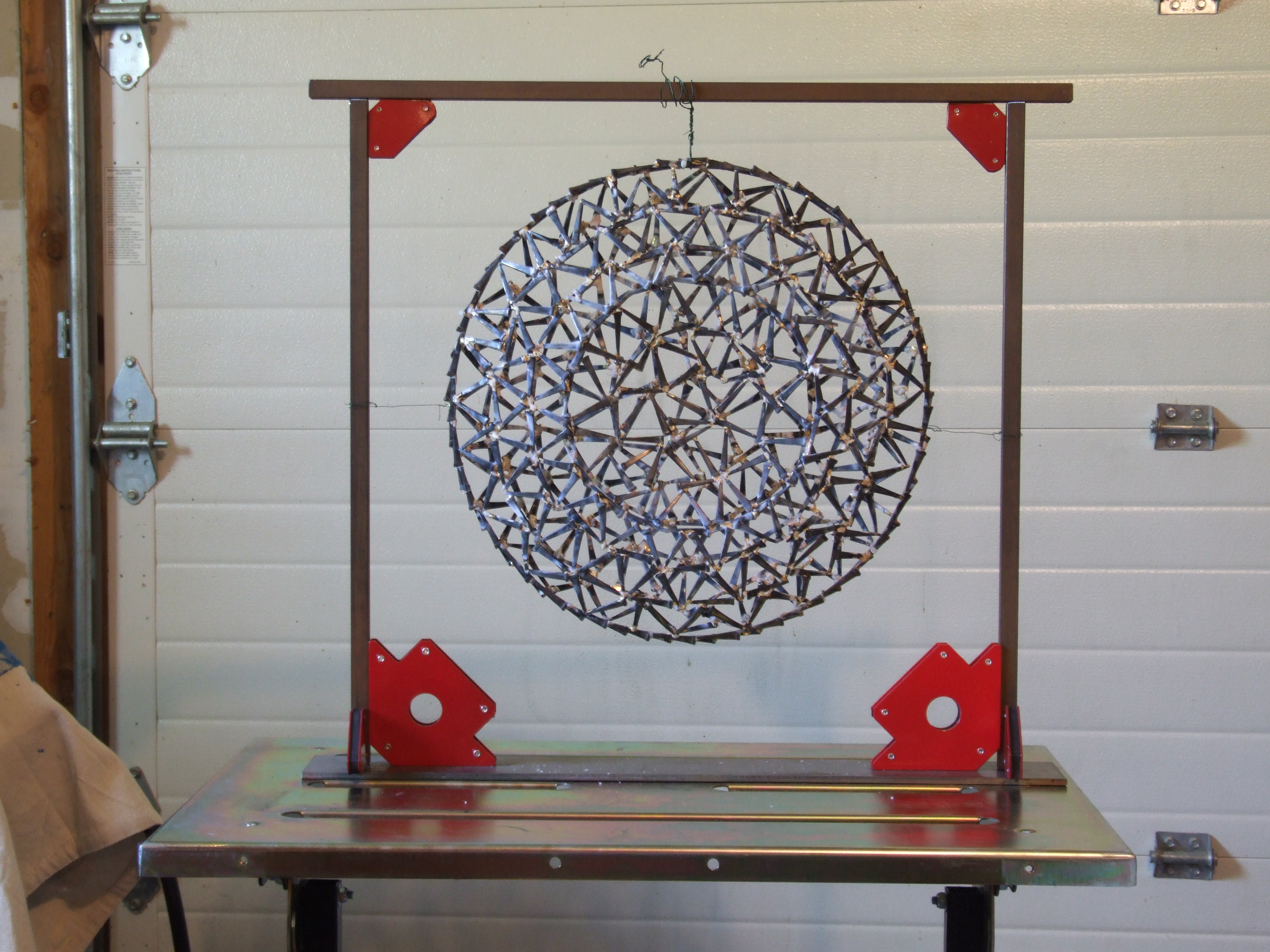

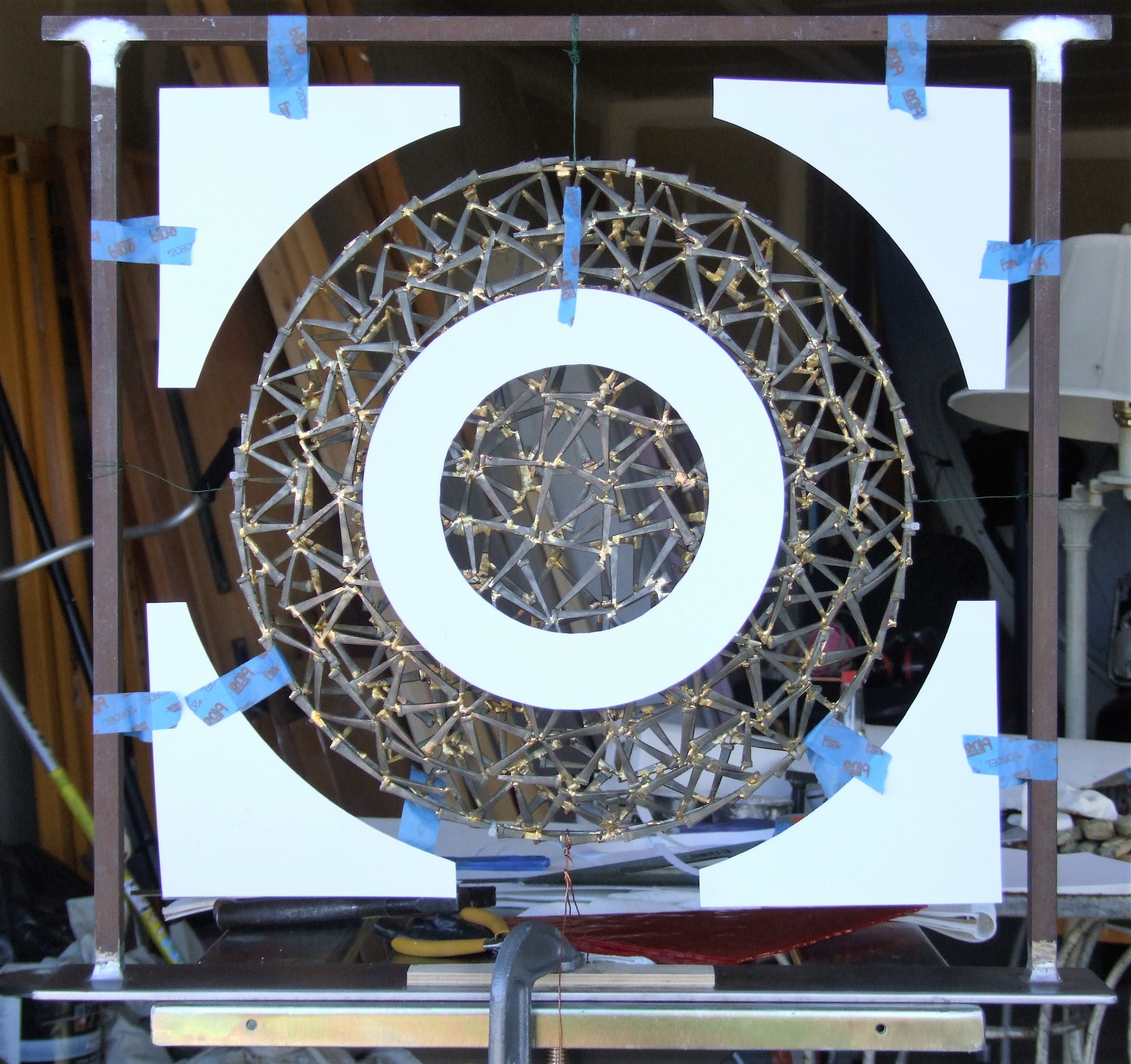

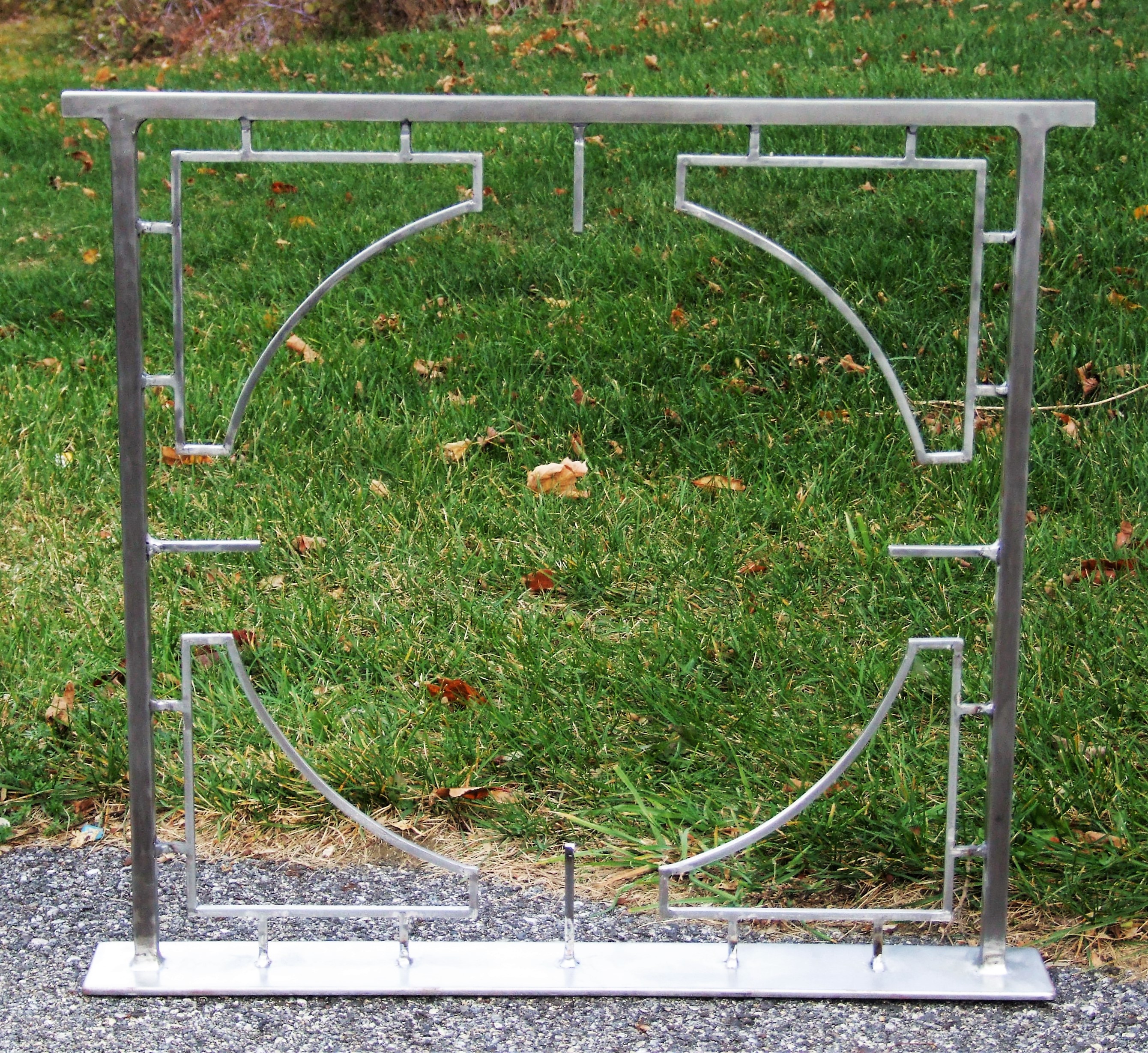

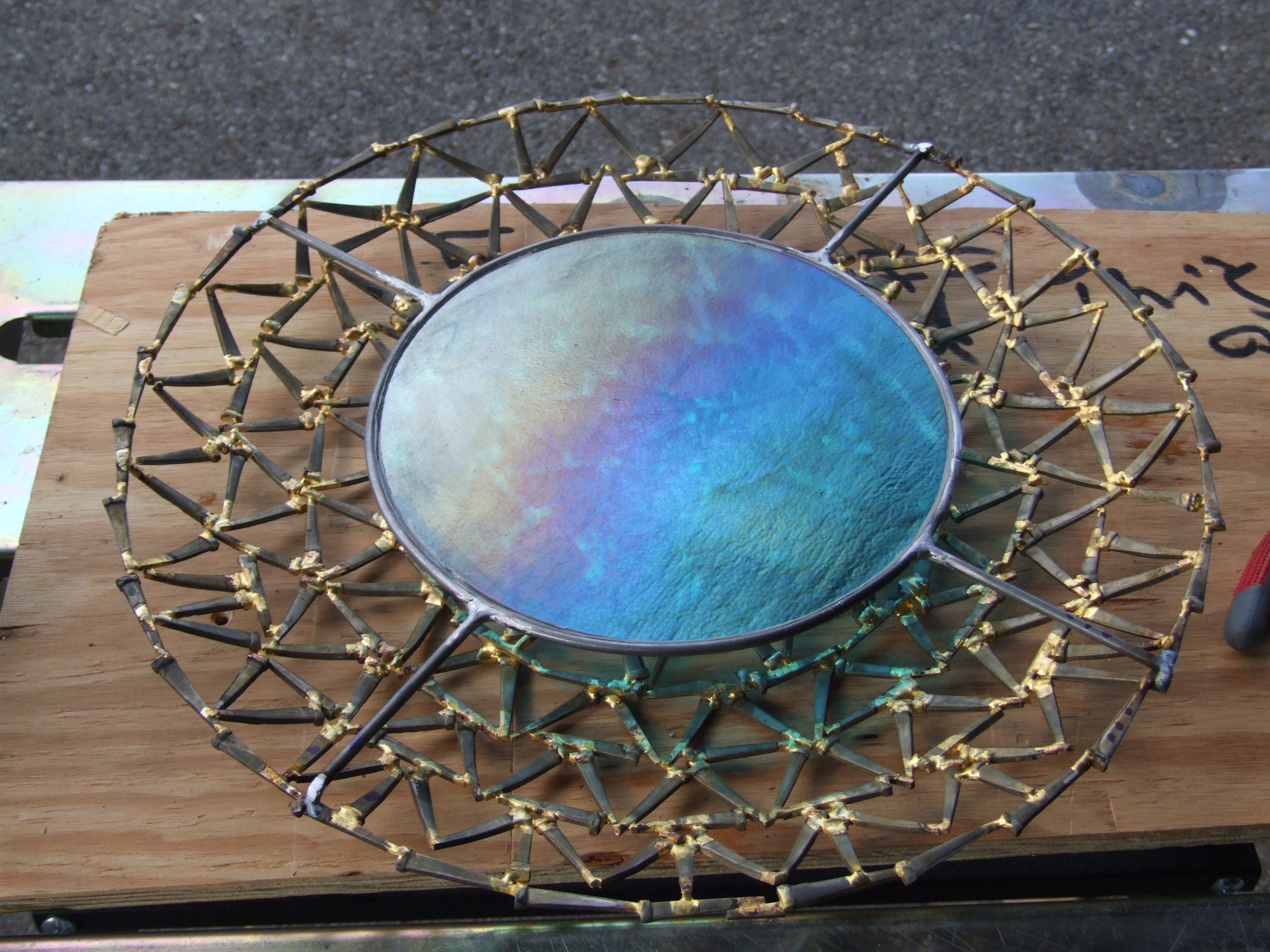

AJNA (third eye)

AJNA (third eye)

Using the mold as a fixture, antique flooring nails were bent, placed, and brazed using bronze rod and an oxy-propane torch. Once two halves were created, a steel frame was designed and MIG welded together. The circular inner bracket for the blue glass was created in steel rod and welded to one of the two Icon halves. Fine art glass was placed into the four brackets, and into the center ring. The two halves of the Icon were then welded permanently together.

Lucy

Lucy is a concept piece. It is an homage to an early hominin find in Ethiopia: Australopithecus afarensis, nicknamed - Lucy. The piece unites the person who Lucy was (and it is meaningful to remember that she was a person), her lineage to us, the searchers who discovered her, and the technicians who delicately reassemble all such precious finds - incomplete, distorted, and missing structure. The Icon in this piece offers a duality between the frailties of material and the perfection of meaning.

Steel is one of a series of pieces being produced from the same graphite mold. See the Graphite section for details. Graphite has the property of heat resistance to several thousand degrees. With care, metal and glass may be worked inside of a graphite form used as a jig, or as a mold. In the case of, Steel – mild steel bearings were placed inside the mold using sand for positioning. The bearings were gathered into the desired shape and then MIG welded. The welding produced an organic, marine texture over the two forms produced. These forms were aligned into a cross-section of the Icon template and welded to a steel rod mount. At this point, the piece was cleaned and prepped for patina, which was applied and then sealed. Finally, 3/8” steel plate was cut and welded to form a base. The base was ground and brought to a high polish to create stark contrast in two conditions of steel: one of deep 'marine' oxidation, and the other of bright polish.